Ever wondered about what makes harsh-environment assemblies more robust?

Harsh environments don’t usually cause electronics to fail overnight. As time goes on, factors in the field expose weaknesses in unprepared systems, factors such as:

- Thermal cycling

- Vibration

- Moisture

- Continuous operation

For engineers and purchasers alike, harsh-environment reliability is rarely about a single feature. It’s shaped by how assemblies are built, protected and controlled over their full lifecycle.

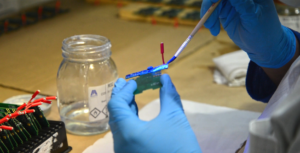

Conformal Coating

Where Robustness is Really Decided

In harsh environments, a few areas consistently make the difference:

- Long-life Planning and Redundancy – Many harsh-environment systems are expected to run for years, often with limited opportunity for redesign. Long-buy strategies help manage obsolescence, while designed-in redundancy ensures a single fault doesn’t take down the system where failure isn’t an option. Reputable CEMs will work with you to design systems for longevity and quality to make sure all cases are covered with your design.

- Safety-critical Parts – Some components can’t be changed once a system is in service. These are classed as safety-critical because failure would have serious consequences — whether through regulation, access constraints or safe operation. Getting those choices right first-time matters. We make sure your parts are quality by sourcing from trusted, audited suppliers, saving you time and

- Test Before You Protect – Once an assembly is conformally coated or potted, fault-finding becomes difficult and expensive. That’s why experienced CEMs adopt a test-before-protect approach – using functional and jig testing to verify performance before sealing anything in. Using OEM supplied testing specifications, your CEM should ensure your standards are upheld.

Protection Strategies That Fit Harsh Environments

- Conformal Coating is typically used to protect against moisture, corrosion and contamination while maintaining serviceability. Conformal coating also allows for some PCBs to be repaired, as the coating can be delicately removed to replace or update components.

- Encapsulation (Potting) is chosen where conditions are more severe, offering maximum protection against shock, vibration and aggressive environments, with reduced access for repair.

- In extreme applications, both may be used together – coating first to protect fine features, then potting to provide long-term mechanical and environmental robustness.

Encapsulation (Potting)

Traceability, documentation and Audit trails

In harsh environments, issues don’t always show up immediately. Full traceability and a clear audit trail allow materials, components and processes to be tracked years later. Supporting documentation, including CofC’s, DofC’s and FAIR’s, provides confidence that what’s operating in the field is exactly what was built, tested and approved.

To really see if your product has been made according to standard, looking out for AS1900D and ISO9001 certifications associated with your CEM is integral. Quality approvals requiring regular scheduled and unscheduled audits, help assure that your CEM can provide a trusted and tested, functional product that adheres to the standards you require, be it ATEX, IECEx or IPC Level 3.

Creating safe electronics isn’t about over-engineering. It’s about understanding trade-offs, managing lifecycle risk early, and building assemblies that behave predictably long after deployment. At Mowden, we’ve been manufacturing ATEX & IECEx approved PCBs since 1970. If you’ve got important equipment to make, we can help you get it right first time.

Learn more about our capabilities and get in touch: