THE COMPLETE ELECTRONICS SOLUTION

Manufacturing Overview

With over 55 years of manufacturing expertise we add exceptional value to our customers by providing end-to-end solutions to compliment our core services.

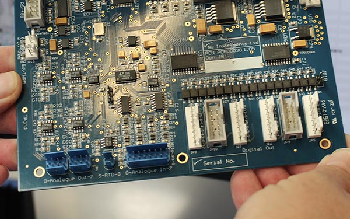

Ranging from value engineering in design, to FAIR reporting, customised testing and special processes, we are trusted in our ability to deliver scalable solutions, from PCB assembly only to complete finished products.

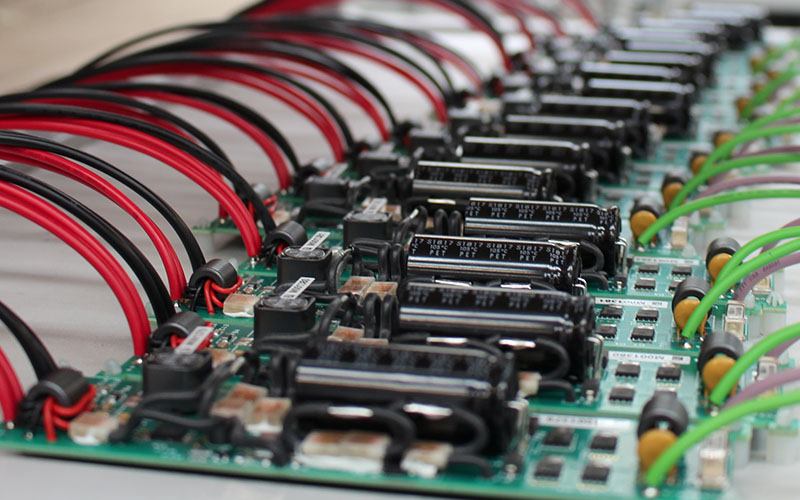

Surface Mount Assembly

- 100% Automated Optical Inspection

- Leaded and lead-free (ROHS Compliant) assemblies

- Ability to place all types of components including BGA’s, QFN’s and QFP’s, ranging in size from the smallest 01005 casings increasing to 56x56mm²

- Industry leading DEK solder paste printing

- High speed accurate placement of up to 16,000 components an hour.

- Fast changeover time between batches.

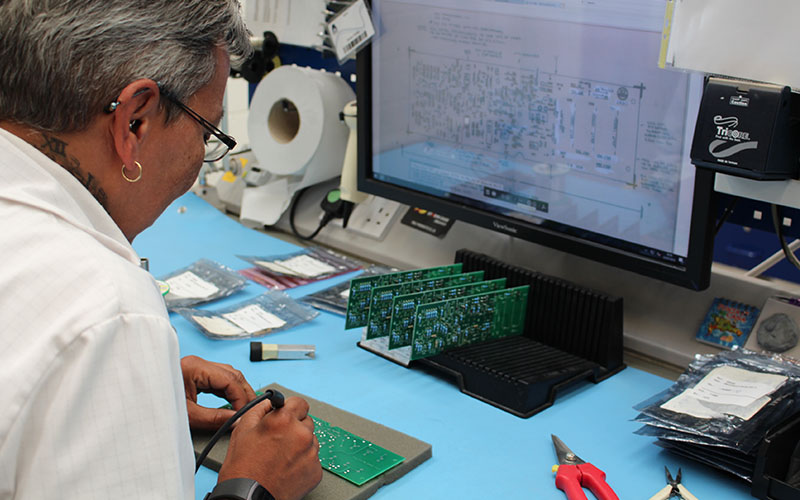

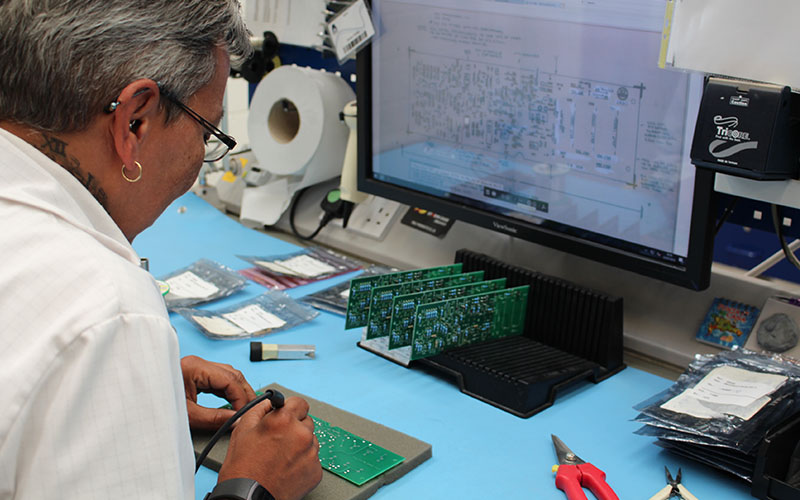

Conventional Assembly – Through Hole

Using conventional, through-hole PCB assembly methods, Mowden have over 50 years experience manufacturing assemblies from straightforward to highly complex specifications. Our experienced team of operators are fully trained to the latest IPC-A-610 standards.

- Up to IPC Level 3 for critical assemblies

- In-house rework facility

- Dedicated Lead-free and Leaded soldering stations

- In-cell manufacture and test for CEM assemblies

- RoHS and non-RoHS precision hand-soldered assembly

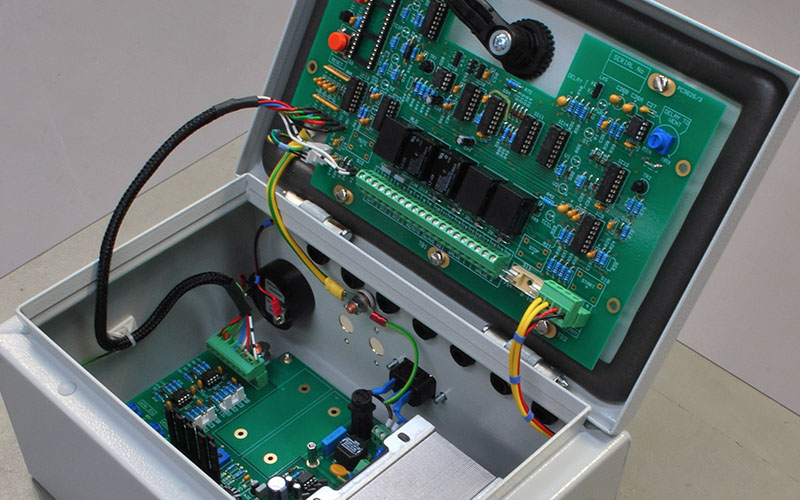

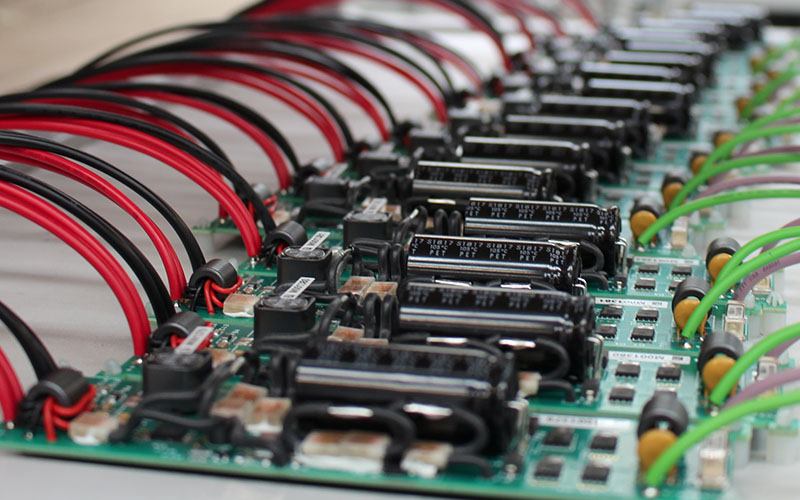

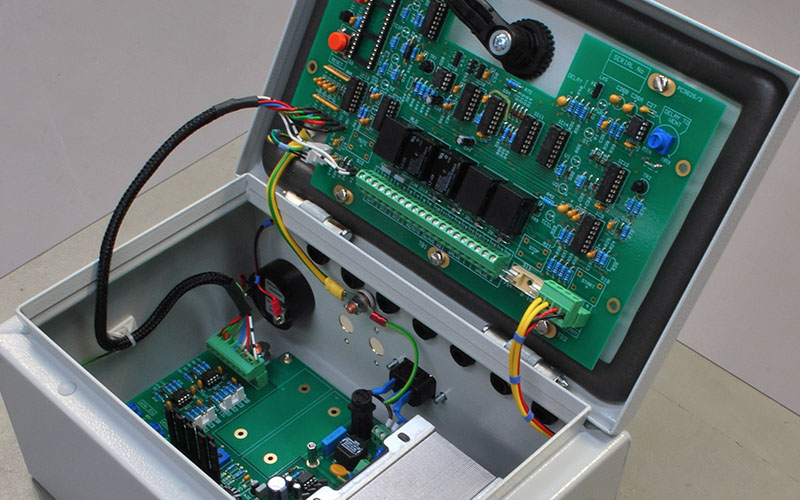

Box Build & Cable Wiring

At Mowden, we offer a complete build service with fabrication on-site at our UK factory. We can design and populate your boards and assemble them into your complete product, making the process of product build and distribution easy to manage and as cost effective as possible. Our customers can then focus on their core competencies such as design and final assembly. All complete products are given rigorous checks throughout the build process to make sure the finished product is reliable. We also offer wiring, looming and metal fabrication on site.

- Either full or partial enclosure build depending on requirements

- Cable wiring and looming to IPC-620

- Precision CNC machine shop on site for ultimate flexibility in low volume, low tolerance

machining incorporated into a PCB box build. Click here for more information.. - Strategic supply chain for components such as complex machined enclosures and Mil- Spec connectors

- All assemblies are subject to rigorous checks throughout the build. Final inspection prior to dispatching from Mowden then ensures our customers’ strict order fulfilment and logistics demands are met.

Precision Machine Shop

In order for us to mitigate risk in the supply chain and to enable us to significantly increase flexibility for our customers, we have operated a precision machine shop for over 10 years at our UK factory.

- We are able to complement PCB assemblies with a complete build service including housings for bespoke, low volume/ high precision machining of plastics and metals. Our ability to work with low tolerances with our range of CNC and finishing equipment.

- The increased flexibility is channelled into metal and plastic assemblies, bespoke jigs and sub-assembly components, allowing quick turnaround times for our clients on bespoke projects. Often this also negates any outsourcing risk or potentially our customers having to integrate themselves at final assembly stage, freeing up valuable time.

NPI & Prototyping

Recognising that time-to-market is vital, we enable a smooth production introduction and seamless transition to volume manufacturing. This ensures our customers maximise their business opportunities with a timely market entry. All new product introductions are carried out in an IPC-A-610 environment, and we use Mycronic (formerly MYDATA) SMT machines, known for their flexible capability.

- We understand that confidentiality and security of our customers IP is paramount. Because of this we encourage and regularly agree a Non Disclosure Agreement (NDA) before any exchange of information, which is flowed down the supply chain.

- Feasibility studies

- Right first time approach

- Potential cost reduction at the design stage

- Large 18,000 sq ft facility for scaleable production solutions

Supply Chain

Strategic suppliers for us means trusted, high quality and local wherever possible. Building strong relationships and having flexibility and ease of communications are paramount.

- Industry require its sub-contract manufacturing partners to employ the highest of quality standards

- Full traceability of components where required

- Approved supplier listing, auditing and performance

- 100% sustainable on time delivery and quality

- Supplier performance

- Compiling FAIR reports

Design and Development

Our engineering team has vast experience in working with product development in a diverse array of areas. From initial concept right through to manufacture, we will work with you to develop your product, ensuring we provide the right solution.

By monitoring the latest trends and developments in the industry, we are able to customise the latest software, firmware and wireless communication methods to fully support our customer needs for fast and accurate data collection.

- Feasibility studies

- Risk mitigation

- Design for manufacture or build to print

- Value Engineering (working cost-out where possible)

- Software programming and seamless integration into quick access applications

Conformal Coating and Encapsulation

Mowden have vast experience in applying a variety of conformal coating (varnishing) and encapsulation (potting) solutions. These are customised to suit each individual assembly and it’s intended environment.

Dedicated in-house workstations using specialist equipment are used for the application of resins such as epoxy and silicone, which offer outstanding protection for components against harsh environments and long-term reliability in the field.

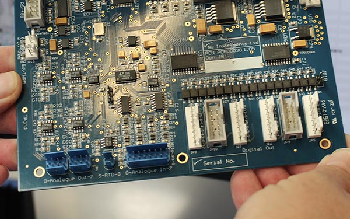

Test & Inspection

The most appropriate level and nature of testing can be determined to balance complexity, style and product function. Wherever possible, our CEM testing is carried out in-line with production to maximise efficiency, early detection and cost effectiveness for our customers.

Our customers often rely on us to work to complex test procedures in order to reduce final testing requirements at their site and save valuable time.

- Baseline to complex testing

- 100% AOI 3D automated inspection on all SMT assemblies

- Full functional test to your specification or a collaborative engineer-led solution

- Custom jig assemblies

- RF Testing

- In cell testing

- In circuit testing

- Automated inspection equipment for some complex components

Ongoing Support

All our PCB assemblies are covered by a comprehensive 1 year warranty service, ensuring quick turnaround for minimum customer impact. Repairs to assemblies out of warranty are also available on request.

With over 60 years of manufacturing expertise we add exceptional value to our customers by providing end-to-end solutions to compliment our core services.

Ranging from value engineering in design, to FAIR reporting, customised testing and special processes, we are trusted in our ability to deliver scalable solutions, from PCB assembly only to complete finished products.

Mowden have continually invested in technology to enable the placement of some of the smallest SMT components in the industry. We use fully automated Mycronic (formerly MYDATA) SMT technology, which is known for its accuracy and flexibility in addition to being extremely capable on low or high-volume applications.

- 100% Automated optical inspection

- Leaded and lead-free (RoHS compliant) assemblies

- Ability to place all types of components including BGA’s, QFN’s and QFP’s, ranging in size from the smallest 01005 casings increasing to 56x56mm²

- Industry leading DEK solder paste printing

- High speed accurate placement of up to 16,000 components an hour

- Fast changeover time between batches

Using conventional, through-hole PCB assembly methods, Mowden have over 50 years experience manufacturing assemblies from straightforward to highly complex specifications. Our experienced operators are fully trained to the latest IPC-A-610 standards.

- Up to IPC Class 3 for critical assemblies

- In-house rework facility

- Dedicated lead-free and leaded soldering stations

- In-cell manufacture and test for CEM assemblies

- RoHS and non-RoHS precision hand-soldered assembly

At Mowden, we offer a complete build service with fabrication on-site at our UK factory. We can design and populate your boards and assemble them into your complete product, making the process of product build and distribution easy to manage and as cost effective as possible. Our customers can then focus on their core competencies such as design and final assembly. All complete products are given rigorous checks throughout the build process to make sure the finished product is reliable. We also offer wiring, looming and metal fabrication on site.

- Either full or partial enclosure build depending on requirements

- Cable wiring and looming to IPC/WHMA-A-620

- Precision CNC machine shop on site for ultimate flexibility in low volume, low tolerance machining incorporated into a PCB box build. Click here for more information.

- Strategic supply chain for components such as complex machined enclosures and Mil- Spec connectors

- All assemblies are subject to rigorous checks throughout the build. Final inspection prior to dispatching from Mowden then ensures our customers’ strict order fulfilment and logistics demands are met.

In order for us to mitigate risk in the supply chain and to enable us to significantly increase flexibility for our customers, we have operated a precision machine shop for over 10 years at our UK factory.

- We are able to complement PCB assemblies with a complete build service including housings for bespoke, low volume/ high precision machining of plastics and metals. Our ability to work with low tolerances with our range of CNC and finishing equipment.

- The increased flexibility is channelled into metal and plastic assemblies, bespoke jigs and sub-assembly components, allowing quick turnaround times for our clients on bespoke projects. Often this also negates any outsourcing risk or potentially our customers having to integrate themselves at final assembly stage, freeing up valuable time.

Recognising that time-to-market is vital, we enable a smooth production introduction and seamless transition to volume manufacturing. This ensures our customers maximise their business opportunities with a timely market entry. All new product introductions are carried out in an IPC-A-610 environment, and we use Mycronic (formerly MYDATA) SMT machines, known for their flexible capability.

- We understand that confidentiality and security of our customers IP is paramount. Because of this we encourage and regularly agree a Non Disclosure Agreement (NDA) before any exchange of information, which is flowed down the supply chain.

- Feasibility studies

- Technical Project Manager to carefully coordinate projects from start to finish in addition to day-to-day account management.

- Right first time approach

- Potential cost reduction at the design stage

- Large 18,000 sq ft facility for scaleable production solutions

Strategic suppliers for us means trusted, high quality and local wherever possible. Building strong relationships and having flexibility and ease of communications are paramount.

- Industry requires its sub-contract manufacturing partners to employ the highest of quality standards

- Full traceability of components where required

- Approved supplier listing, auditing and performance

- 100% sustainable on time delivery and quality

- Supplier performance

- Compiling FAIR reports

Our engineering team has vast experience in working with product development in a diverse array of areas. From initial concept right through to manufacture, we will work with you to develop your product, ensuring we provide the right solution.

By monitoring the latest trends and developments in the industry, we are able to customise the latest software, firmware and wireless communication methods to fully support our customer needs for fast and accurate data collection.

- Feasibility studies

- Risk mitigation

- Design for manufacture or build to print

- Value engineering (working cost-out where possible)

- Software programming and seamless integration into quick access applications

Mowden have vast experience in applying a variety of conformal coating (varnishing) and encapsulation (potting) solutions. These are customised to suit each individual assembly and it’s intended environment.

Dedicated in-house workstations using specialist equipment are used for the application of resins such as epoxy and silicone, which offer outstanding protection for components against harsh environments and long-term reliability in the field.

The most appropriate level and nature of testing can be determined to balance complexity, style and product function. Wherever possible, our CEM testing is carried out in-line with production to maximise efficiency, early detection and cost effectiveness for our customers.

Our customers often rely on us to work to complex test procedures in order to reduce final testing requirements at their site and save valuable time.

- Baseline to complex testing

- 100% AOI 3D automated inspection on all SMT assemblies

- Full functional test to your specification or a collaborative engineer-led solution

- Custom jig assemblies

- RF testing

- In cell testing

- In circuit testing

- Automated inspection equipment for some complex components

All our PCB assemblies are covered by a comprehensive 1 year warranty service, ensuring quick turnaround for minimum customer impact. Repairs to assemblies out of warranty are also available on request.